How we benefit:

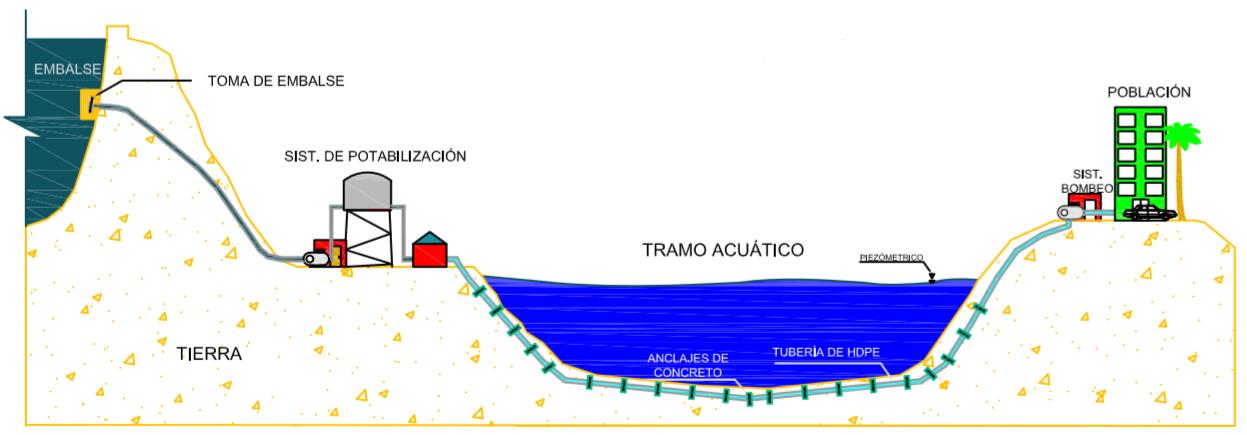

Aqueducts submarines are used to transport drinking water or raw water through seas, rivers or lakes, in order to serve populations that are isolated by these aquatic environments.

Several submarines aqueducts are currently installed in different parts of the world, carrying water to islands from the mainland, crossing gulfs and passing rivers and lakes found in the most feasible route to bring the service to towns that need it for not having own resource of water in amounts sufficient for its development.

An example of underwater aqueducts in operation can be found in Venezuela, currently serving the islands of Margarita and Coche, in the state of Nueva Esparta, carrying water from reservoirs and Clavellino Turimiquire, both located in the Sucre State. These aqueducts total more than 120 km of pipe of various diameters (from 200-900 mm) and carry a total of 3200 l / s, to attend a population of approximately 490,000 inhabitants, totaling nearly 700,000 people in seasons of rest with the influx of vacationers (estimated figures for 2012).

Why HDPE:

There are many advantages provided by the construction of these aqueducts pipes HDPE High Density Polyethylene (DHPE acronym in English). Today it can be considered that the HDPE is the most reliable and economical choice when submerged systems it is because it can have the benefits of a material that is not attacked by corrosion of the marine environment, achieving a system with greater life (over 60 years) being maintenance free; with great flexibility to absorb the irregularities of the seabed and earthquakes; and large hydraulic advantages to drive higher flows with lower friction losses, due to the low fouling the inner walls of the pipe.

How are built:

The transport is usually carried out from a reservoir located on the mainland, through an aquatic area, which is constructed with a HDPE pipe system with reinforced concrete counterweights that are installed in solidarity along the pipeline. These submarines aqueducts must be built through long stretches of welded pipes continues its flanged ends, approximate lengths between 300 and 500 m, which are prepared on the ground and then are taken floated to the installation area to sink so on the seabed.

The long stretches are interconnected by means of flanges, bolts and gaskets stainless steel high pressure, allowing seal the system. To ensure adequate protection of the aqueduct is necessary to make an underwater trenching to bury the pipe and leave it out of the reach of ocean currents and possible clashes with anchors or trailers with fishing nets, especially at lower depths of 10 m where reach higher magnitudes of currents that can affect system stability.

For the design of a submarine pipeline should be available with current studies and bathymetry that reveal in detail the necessary variables to make structural calculations and choose the best route to position the pipe on the underwater bed. Particularly in submarine aqueducts (unlike outfalls) should have systems of dampers, which are part of the counterweights concrete to limit the efforts that may result from the expansion of the pipe to the internal pressure increased system .

Author: Ing. Sergio Elena

www.elinsubca.com

Gracias a mis amigos de ELINSUBCA por tenerme presente en sus comentarios y proyecto ejecutados. Agradecido y siempre estare dispuesto a recibir cualquier artículo correspondiente a sus trabajos En twiter ; @laya gil para servirles……

Hola Gerónimo, gracias por tu comentario, esperamos que siempre sean útiles nuestros artículos. Estamos para servirles

Seria interesante conocer los costos por tramo de la tubería e intalacion o por lo menos un estimado, con el fin de poder hacer comparaciones frente a otras alternativas. Gracias

Muchas gracias Sr. Sebastian Perez por su pregunta,le informamos que ha sido trasmitido su duda técnica al Departamento de Proyectos, en cuestión de horas le será respondida su pregunta.

Estimado Sr. Sebastián Pérez, agradecemos su comentario.

Contar con valores referenciales por tramos de tubería instalada resulta siempre una información imprecisa por cuanto existen distintos grados de complejidad en cuanto a las condiciones ambientales y de trabajo en cada proyecto, sin embargo nuestra experiencia nos lleva a saber que usar Polietileno de Alta Densidad resulta en menores costos de inversión y de mantenimiento en comparación con otras alternativas tradicionales.

Si usted tiene una necesidad especifica podríamos ayudarle estimando los costos de su proyecto. Igualmente nos estaremos comunicando para hacerle llegar mayor información.