Systems polyolefin sewer pipes have a life expectancy of at least 100 years. This is the conclusion of a recent two-year project commissioned by TEPPFA (Trade association Representing manufacturers and national associations of plastic pipe systems in Europe) and independently analyzed by Professor Heinz Dragaun of the School of Higher Education (TGM) in Vienna . The project involved the excavation of many samples of pipe networks in service were tested and evaluated under laboratory conditions meticulous. It is expected that the results of the analysis and conclusions of this work have a favorable influence on those sewer operators facing large capital investments in new or replacement networks.

Most European countries have outdated sewage systems. They not only leaks and poor performance; also they require replaced or simply be modernized. Life expectancy is a key factor in any investment decision. Systems polyolefin (polypropylene and polyethylene) have been widely used for over 40 years, and compared with non-plastic materials of pipes, consistent solutions have provided longer term. However, while life expectancy polyolefin pipes has been debated for many years, it has never been given a definitive conclusion. Until now.

Greater confidence.

Tony Dalton, General Manager TEPPFA is delighted with the results of the project: “The designers, owners and operators of sewer networks can now be sure that these sewerage systems have a service life of at least a hundred years, when materials, products and installation practices meet the appropriate requirements.

The results are also of vital importance for suppliers of materials, pipe manufacturers and contractors working closely with market sewage system. Obviously it will create more attractive for sewage pipes and allow polyolefin applied with greater confidence, as their yields are consistent throughout his long life as an installed capital. The conditions set by the project team were rigorous and based on real-time data long term. For example, the tests included excavation of pipes that have already been in use for up to 40 percent of their service life offered. These tests showed that there has been a deterioration or excessive degradation during this time.

Tony Calton notes that “although the excavated pipes were manufactured using formulas of first-generation materials, their residual life was estimated at more than 50 years. We should note that current formulations offer performance greater useful life than previous materials “.cien years when materials, products and installation practices meet the appropriate requirements.

The results are also of vital importance for suppliers of materials, pipe manufacturers and contractors working closely with market sewage system. Obviously it will create a greater appeal to the sewer pipes of polyolefin and allow applied with greater confidence, as their yields are consistent throughout his long life as instalado.Otros the capital key factors were investigated during this project, but found that no adversely affected life expectancy. These include the chemical composition of sewage aguae, the temperature profile of sewage flows and changes in installation practices used. the influence of high concentrations of waste water that is typically associated with pipeline systems structured wall was also examined.

The full technical report and a technical summary are available on the website of TEPPFA. A four-page brochure that describes the project scope is also available through the company members TEPPFA and / or members of national associations. It is also important to note that this project was coordinated by TEPPFA together with LyondellBasell, Borealis and TGM (Austria).

Source: TEPPFA. Tony Calton

Translation and Adapted by: Stefan Balabanoff (Consultant Economist)

BASTANTE INTERESANTE EL USO DE ESTE TIPO DE TUBERIAS PARA LOS DIFRERENTES TRABAJOS, DADO QUE LOS MISMOS SE REALIZARIAN CON UN COSTO MENOR DE MTTO Y SU DURACION EN EL TIEMPO ES BASTANTE ESPECTACULAR.

AGRADECIDO DE SU INFORMACION

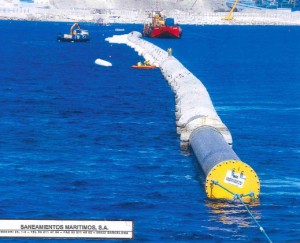

Muchas gracias Sr. Gerónimo por comentar nuestro artículo. Nos alegra que le haya parecido interesante y ciertamente es una excelente opción frente a las necesidades de instalación de tuberías en medios marinos e industriales. Estamos procediendo a incorporarlo en nuestra base de datos para que reciba información técnica asociado a nuestra especialización de tuberías en PEAD. Nos gustaría contar con mayor información sobre usted y su empresa y saber si requiere alguna información adicional que pueda aportar valor a su desarrollo profesional.

Quedamos atentos a su Respuesta.